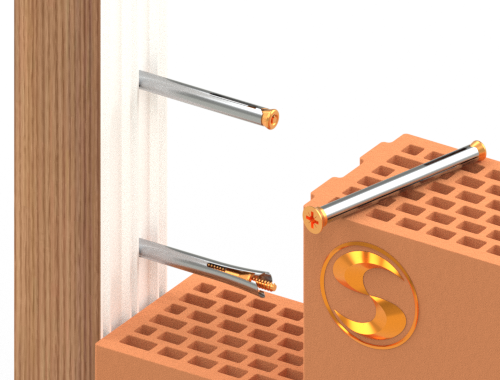

Dowels are one of the methods used to connect window and door frames to the walls of a building. They must be appropriately selected based on the type of the frame and the material of the wall. The Dowels Module in Stolcad® Professional allows displaying of holes for dowels and roller shutter guides already at the design stage. These elements can also be visually presented in offers and production print-outs. The user of the program can precisely set both the position, as well as different diameters of each hole. This approach results in the ability to send fully dimensioned operations to the driver of a machining centre. The module through the visualization of the holes also contributes to more efficient assembly of structures at the destination.

Dowel Bars Module

- Modules

- Dowel Bars Module

Precise placement of holes for dowels and roller shutter guides

Dowels Module - Who is it for?

Companies that need to visualize precise positions of dowel holes and roller shutter guides on projects, offers or production print-outs.

Companies that need to visualize precise positions of dowel holes and roller shutter guides on projects, offers or production print-outs. Companies that produce many windows and doors with non-standard dowel settings, which is a common requirement for example on Western European markets.

Companies that produce many windows and doors with non-standard dowel settings, which is a common requirement for example on Western European markets. Companies that want to include operations of making holes for dowels or roller shutter guides in the driver for a machining centre.

Companies that want to include operations of making holes for dowels or roller shutter guides in the driver for a machining centre. Companies that perform the so-called "furring" operation (milling along the profile for potential spacer strips).

Companies that perform the so-called "furring" operation (milling along the profile for potential spacer strips).Basic functions of the Dowels Module

Defining dowels in Stolcad® Professional

Older versions of Stolcad® supported the insertion of dowels in two diameters. Currently, users of Stolcad® Professional have full freedom to define different types of dowels with varying dimensions. For clarity, different diameters of dowels on projects are drawn in different colours. Also, one can add textual descriptions of dowel diameters, e.g. 8 mm. All this makes designing, production and later installation more efficient.

It is possible to define the distance, how many mm from the edge of the frame a specific type of dowel should be placed, and also the maximum allowable distance between dowels. A rule can also be enabled to prevent placing a dowel where a post is located. The order of inserting posts and dowels does not matter, as the program automatically calculates their proper distribution. Manual editing of the position and diameter independently for each dowel is also possible.

Methods of inserting dowels on designs of windows and doors

Dowels in Stolcad® Professional can be inserted into windows and doors in two ways: automatically or manually. The first method significantly speeds up the design process. The second method allows for the introduction of custom settings and full control over the precise position of each dowel hole.

Automatic dowel insertion

This method is especially recommended for users designing numerous structures using standard dowel positions. The program allows automating the process of inserting dowels by defining rules, which for example will always place dowels on the left, top and right sides in a new window design. It is possible to set separate dowel insertion rules for each side of a window or a door with each new design, or window selected from the library of the ready-made shapes (schemas). In this approach, it is sufficient to indicate, when designing, from which side of the structure the dowels should be introduced, and the program will immediately place them. A major advantage of this method is the automatic adjustment of the number and the distribution of dowels in case of changes in drawing dimensions.Manual adjustment of positions of dowels

The automatic dowel insertion method is not the only option. At any time, you can switch to manual control and freely add, remove or change the position of dowels. The user can precisely place individual dowels and also change their type. As a result, different types of dowels can be used on one side of the window, e.g. 6.5 mm and 10 mm. Each side of the window – left, top, right and bottom – can be configured independently. In the manual modification mode, the program assumes that the user is advanced and independently controls the position of dowels relative to the position of posts as well as when modifying drawing dimensions. In such cases, the user personally oversees the correctness of the dimensions.Adjustment of dimensional axes with dowels

The module enables the display of additional dimensional axes showing the position of dowels. The appearance of these axes is fully customizable. One can specify how dowel dimensions are presented, i.e., they can be measured from the start of the project or as differences between their positions. Users can customize the appearance of the dimensional axes to their own needs, such as setting margins, line thickness, font size and position, colour, presence of arrows, and even determine the order of displaying each axis on the project.

Similarly like other drawing settings options, the position of dowels can be independently enabled on the screen, offer print-out and production print-out. The clients using the Production Management Module will have dimensioned dowels also displayed on production monitors, allowing for on-going monitoring and control of their precise positioning during the production process. This increases the accuracy and efficiency of the production by ensuring that all elements are correctly positioned according to the project.

Advanced features of the Dowel Module

Customization of the dowel dimension from the frame and post axis in the automatic insertion method

Another feature is to ensure that in the automatic calculation of dowel positions, their dimensions do not overlap with positions of the posts. This eliminates the situation where the position of the dowel might conflict with the post connector. You can specify a different distance to the first dowel from the frame edge and another from the post axis in a specific project.

Users may optionally indicate that in addition to fixed posts, movable posts should also be considered. Of course, if the distance between the extreme dowels is less than the minimum distance, the program will only insert one dowel in the middle, in order to avoid placing two dowels too close one from another. Because of these features, you can be sure that all dowels are placed according to the best practices.

An alternative method of inserting dowels - introducing an independent gap to the dowel for each profile

Another advanced feature of the module is the ability to customize the behaviour of dowels depending on the profile used. Some technologies recommend that the gap to the first dowel should be measured as a fixed dimension from the inner part of the frame. Our solution allows you to define, independently for each profile, the gap to the first dowel. This applies to both frames and post axes. As a result, the program will take into account different widths of frames and posts when automatically inserting dowels.

For example, on the sides of a door frame, the program will automatically place the first dowel differently at the top and differently at the bottom (at the threshold). Deciding to use this solution in a specific project, the program retrieves data from the appropriate profile packages, ignoring default settings for the dowel gap from the edge and axis. The described method speeds up the automation of dowel entry, eliminating the need for manual modifications in frequently recurring cases. This is particularly useful when selling windows and doors to Western European markets.

The features of the module related to the holes for external roller shutter guides

The module also finds application in determining data concerning holes for screwing in external roller shutter guides. The program is flexible, allowing for specifying operations to screw in roller shutters on every side of the window and on the posts. This makes it possible to fully prepare frame profiles and posts for installation, shortening the time of the final order realization.

Similarly as in the case of dowels, the user can freely define different screwing operations for roller shutters, individually treating different hole diameters and additionally specifying the necessary Y dimension which depends on the profile width and guide. The holes for roller shutter guides can be inserted automatically or manually, as it is with dowels.

Extension to the driver for machining centre to handle operations related to dowels or roller shutter guides

The described module is essential for companies that would like to perform operations related to dowels or roller shutter guides with the use of the driver for a machining centre. One of such operations might be marking holes. However, it is worth noting that machine drivers are always large projects, individually developed by us according to our client's needs.

It is important that to undertake such a project, appropriate tools must be coded on the machining centre by the machine service, and our technical department must introduce the correct macros of these tools into Stolcad® Professional. If you are interested in such a project, please contact us directly, as the scope of such an undertaking significantly exceeds the standard use of the presented module.

The additional feature of the module: including furring operation

The furring operation involves CNC milling along the entire profile. A typical application is milling a place for setting an additional spacer strip of the special installation of the finishing material. During the design, you need to mark the profile on which this processing is to be performed. This is done in a similar way as inserting dowels.

If you do not have a machining centre equipped with such a tool, inserting a furring operation will also draw lines on the appropriate profile. This will be clearly marked for workers who receive such drawings with markings on the production print-outs.

***

If the features of the Dowels Module have piqued your interest or if you would like to discuss your specific requirements, we encourage you to contact our Customer Service Office. Our team is at your disposal.

Fill in the form or call: +48 56 642 66 33